推薦消息更多>>

推薦消息更多>>脈沖除塵器的工作原理介紹

- 來源:http://www.4wpk.cn/ 日期:2023-10-05 發(fā)布人:admin

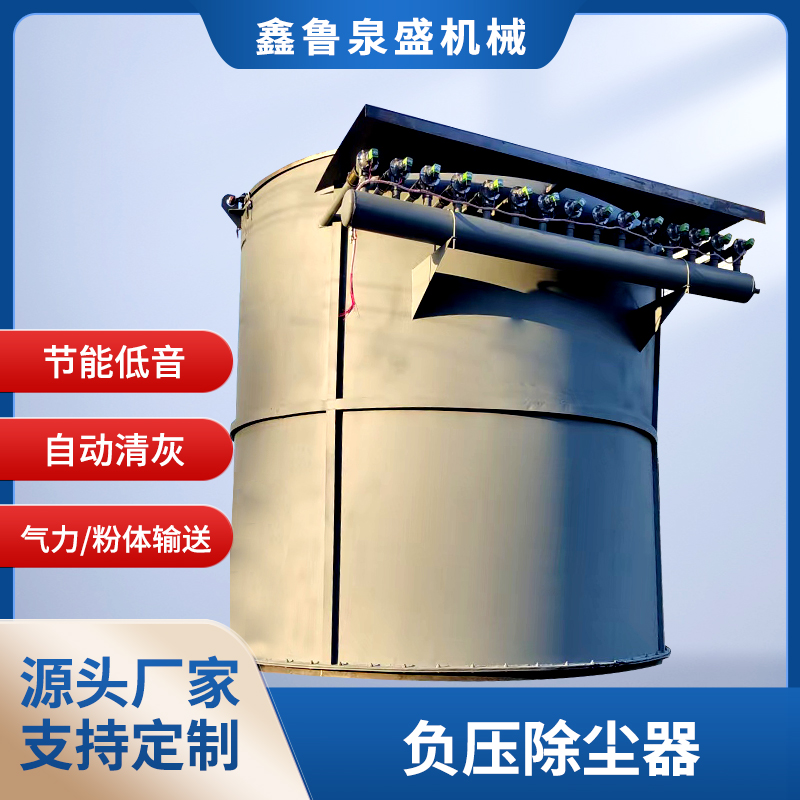

脈沖除塵器是一種高效的空氣污染控制設(shè)備,主要用于工業(yè)領(lǐng)域的粉塵處理。它通過脈沖噴吹清潔技術(shù),能夠有效地去除粉塵顆粒,減少工業(yè)生產(chǎn)過程中對環(huán)境的污染,保護人類健康,并提高產(chǎn)品質(zhì)量。

Pulse dust collector is an efficient air pollution control equipment mainly used for dust treatment in the industrial field. It can effectively remove dust particles, reduce environmental pollution during industrial production, protect human health, and improve product quality through pulse jet cleaning technology.

脈沖除塵器的工作原理是將沉積在濾袋上的粉塵顆粒利用高壓風扇噴吹下來,再通過輸送系統(tǒng)輸送到粉塵倉中,最后通過排放口排放出去。其工作過程包括清洗階段和吸塵階段。清洗階段是指濾袋中的風力噴射氣流將附著在濾袋上的粉塵顆粒抖落下來,脈沖除塵器,脈沖除塵器價格,脈沖除塵器廠家從而實現(xiàn)濾袋的清潔;吸塵階段是指進料系統(tǒng)將產(chǎn)生的廢氣引入脈沖除塵器內(nèi),經(jīng)過脈沖噴射,使粉塵顆粒被清除,凈化后的氣體經(jīng)過排氣管排放出去。

The working principle of a pulse dust collector is to use a high-pressure fan to blow down the dust particles deposited on the filter bag, then transport them to the dust bin through the conveying system, and finally discharge them through the discharge outlet. The working process includes the cleaning stage and the vacuum stage. The cleaning stage refers to the process where the wind jet airflow in the filter bag shakes off the dust particles attached to the filter bag, and the price of the pulse dust collector and pulse dust collector are determined by the manufacturer to achieve the cleaning of the filter bag; The dust suction stage refers to the introduction of waste gas generated by the feeding system into the pulse dust collector, which is then pulsed to remove dust particles. The purified gas is then discharged through the exhaust pipe.

脈沖除塵器具有許多優(yōu)點。首先,它的除塵效率高,能夠去除微小的粉塵顆粒,使廢氣達到國家排放標準。其次,它可以處理大風量的廢氣,適用于各種工業(yè)生產(chǎn)環(huán)境。再次,由于采用了脈沖噴吹清潔技術(shù),可以延長濾袋的使用壽命,降低了維護成本。此外,脈沖除塵器還有自動控制系統(tǒng),可以根據(jù)實際情況進行調(diào)節(jié),保證除塵效果和設(shè)備的安全運行。

Pulse dust collectors have many advantages. Firstly, its dust removal efficiency is high, which can remove small dust particles and make the exhaust gas meet national emission standards. Secondly, it can handle high air volume exhaust gas and is suitable for various industrial production environments. Once again, due to the use of pulse jet cleaning technology, the service life of the filter bag can be extended and maintenance costs can be reduced. In addition, the pulse dust collector also has an automatic control system that can be adjusted according to the actual situation to ensure the dust removal effect and safe operation of the equipment.

脈沖除塵器的應用范圍非常廣泛。它可以在鋼鐵、建材、化工、礦山等行業(yè)中用于處理各種煙氣、塵氣、廢氣。在鋼鐵行業(yè)中,脈沖除塵器被廣泛應用于高爐、燒結(jié)機、煉鋼廠等設(shè)備的煙氣處理。在建材行業(yè)中,它可以應用于水泥爐、石膏爐等設(shè)備的塵氣處理。在化工行業(yè)中,脈沖除塵器可以處理化工生產(chǎn)中產(chǎn)生的廢氣,減少對環(huán)境的污染。在礦山行業(yè)中,脈沖除塵器可以應用于礦石破碎、磨礦等環(huán)節(jié)的塵氣處理。

The application range of pulse dust collectors is very wide. It can be used in industries such as steel, building materials, chemical, mining, etc. to treat various types of smoke, dust, and exhaust gases. In the steel industry, pulse dust collectors are widely used for flue gas treatment in equipment such as blast furnaces, sintering machines, and steelmaking plants. In the building materials industry, it can be applied to dust and gas treatment of equipment such as cement furnaces and gypsum furnaces. In the chemical industry, pulse dust collectors can treat the waste gas generated in chemical production, reducing environmental pollution. In the mining industry, pulse dust collectors can be applied to dust and gas treatment in processes such as ore crushing and grinding.

總之,脈沖除塵器是一種高效、節(jié)能的空氣污染控制設(shè)備。它通過使用脈沖噴吹清潔技術(shù),能夠有效地去除粉塵顆粒,凈化廢氣,保護環(huán)境,提高產(chǎn)品質(zhì)量。脈沖除塵器的廣泛應用,使得各行各業(yè)都能夠在生產(chǎn)中更好地控制污染,實現(xiàn)可持續(xù)發(fā)展。隨著科技的不斷進步,脈沖除塵器的性能將會不斷提高,使得其在環(huán)保領(lǐng)域發(fā)揮更大的作用。

In short, pulse dust collectors are an efficient and energy-saving air pollution control equipment. It can effectively remove dust particles, purify exhaust gas, protect the environment, and improve product quality by using pulse jet cleaning technology. The widespread application of pulse dust collectors enables various industries to better control pollution in production and achieve sustainable development. With the continuous progress of technology, the performance of pulse dust collectors will continue to improve, making them play a greater role in the field of environmental protection.

- 上一篇: 降低羅茨鼓風機的阻力的方式

- 下一篇: 旋轉(zhuǎn)供料器的正確的安裝方法

Related products相關(guān)新聞

掃碼微信溝通

掃碼微信溝通